Introduction:

In the fast-evolving world of industrial automation, efficiency, modularity, and reusability are vital to building robust and scalable PLC programs. One of the most powerful tools at a programmer’s disposal is the Custom Function Block (CFB). These blocks allow you to encapsulate specific logic or operations into modular, reusable components—improving readability, reducing redundancy, and enabling faster troubleshooting.

In this article, we’ll explore:

- What function blocks are

- Why you should consider creating custom ones

- How to develop your own custom function blocks

- Practical examples and best practices

What Are Function Blocks?

Function Blocks (FBs) are a type of encapsulated logic used in PLC programming, especially in IEC 61131-3 compliant environments (like Siemens TIA Portal, Codesys, and Schneider EcoStruxure). Think of them as mini-programs or subroutines that can process inputs, store internal states, and produce outputs.

They are ideal for handling:

- Repetitive logic

- Complex calculations

- State-based control systems

- Modularization of equipment like motors, valves, sensors, etc.

Why Develop Custom Function Blocks?

While many PLC programming environments offer built-in FBs for timers, counters, PID control, and more—custom blocks let you tailor logic exactly to your plant’s needs.

Benefits of Custom FBs:

- Reusability: Write once, use anywhere in your program or across projects.

- Modularity: Divide complex tasks into manageable, testable units.

- Standardization: Encourage consistent logic design across your engineering team.

- Ease of Maintenance: Easier to update a single block than re-edit duplicated logic.

- Scalability: Expand systems faster with plug-and-play logic blocks.

Steps to Create a Custom Function Block

Let’s walk through creating a custom FB using a practical example: a Motor Control Function Block.

1. Define Your Requirements

Decide what the block needs to do. For a motor block:

- Inputs: Start, Stop, FaultReset

- Outputs: MotorRunning, MotorFault

- Internals: Timer for delay start, interlocks, status holding

2. Choose Your Development Environment

Most modern PLC software like:

- Siemens TIA Portal

- Codesys

- Schneider EcoStruxure

- Allen-Bradley Studio 5000

…supports custom FBs. The syntax and process vary slightly, but the core concepts remain the same.

3. Create the FB

In your IDE:

- Create a new Function Block.

- Define your Inputs, Outputs, and InOut variables.

- Use internal variables for memory (e.g., start timers, flags).

- Write your logic using Ladder (LD), Structured Text (ST), or Function Block Diagram (FBD).

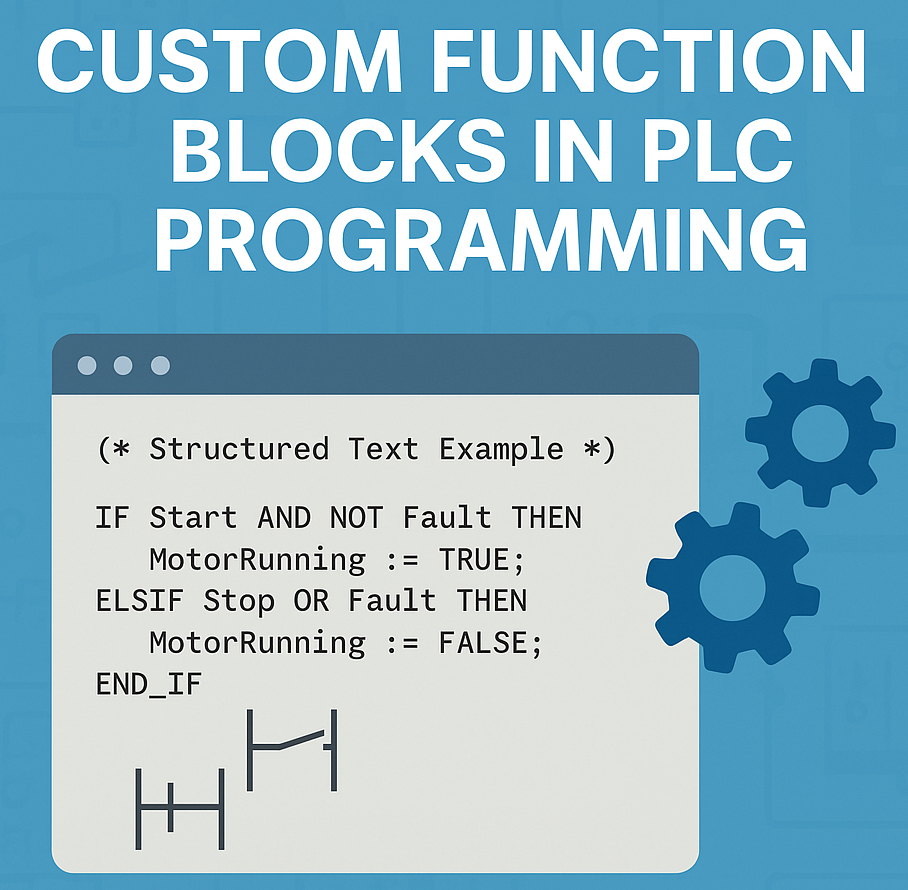

(* Structured Text Example *)

IF Start AND NOT Fault THEN

MotorRunning := TRUE;

ELSIF Stop OR Fault THEN

MotorRunning := FALSE;

END_IF;

4. Test and Simulate

Use a simulator or physical PLC to test your FB:

- Validate each input/output condition.

- Check how it behaves with abnormal inputs.

- Include edge cases like power loss, multiple commands, etc.

5. Document It

Good documentation includes:

- A comment block inside the code

- Description of I/O

- Flowchart or state diagram (optional)

- Version history

Real-World Use Cases for Custom FBs

- Valve Control Block – Handle open/close logic with feedback and alarms.

- Analog Scaling Block – Convert sensor values to engineering units with calibration support.

- Batch Process Controller – Manage steps, timers, and transitions in a recipe.

- Energy Monitoring Block – Track kWh, peak demand, and usage logs.

- Alarm Manager Block – Centralized alarm generation, suppression, and logging.

Best Practices

- Keep It Simple: Focus each FB on a single responsibility.

- Use Naming Conventions: e.g.,

FB_Motor,FB_TankLevel. - Avoid Global Variables: Keep the block self-contained unless necessary.

- Parameterize Wisely: Allow configuration (e.g., delay times, thresholds) via input pins.

- Version Control: Track changes and improvements systematically.

Conclusion:

Custom Function Blocks are game-changers in professional PLC programming. Whether you’re standardizing motor controls across your factory or building smart diagnostics for your processes, CFBs help you do more with less.

Start small—build a block for something you repeatedly use. Over time, you’ll build a library of intelligent components that save engineering hours and improve system reliability.

Have you built your own custom function blocks? Share your experience or questions in the comments below!

Want more tutorials, best practices, and automation tips? Subscribe to PLCExpertHub and stay ahead in your industrial automation journey.