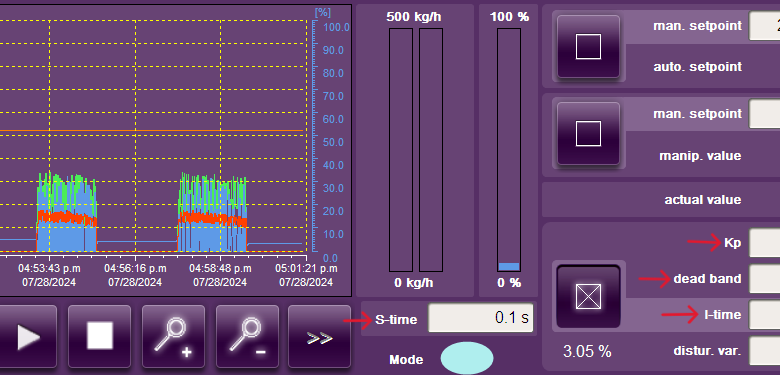

Here’s what the terms on the PID controller screen above mean:

- Kp (Proportional Gain) – This determines how strongly the controller reacts to the difference between the setpoint and the actual value (error). A higher Kp increases the control output response but can lead to instability if too high.

- I-time (Integral Time) – This sets how quickly the controller accumulates past errors and applies corrections. A shorter I-time means faster correction of steady-state errors, but too small a value can cause overshooting.

- Dead Band – This is a range around the setpoint where the controller does not take action. It helps prevent unnecessary small adjustments when the process variable fluctuates slightly around the setpoint.

- S-time (Sampling Time) – This defines how often the controller reads the process variable and updates its control output. A shorter S-time leads to more frequent adjustments but may also increase sensitivity to noise.

- distur. var. (Disturbance Variable) – This represents the impact of external disturbances on the system. It is typically used in advanced control strategies to compensate for unexpected changes in the process.

👍General PID Tuning Approach

- Increase Kp until you see oscillations, then back off slightly.

- Reduce I-time to improve steady-state accuracy but avoid overshooting.

- Introduce a small dead band if fluctuations become excessive.

- Adjust S-time if needed to balance response speed and noise filtering.

- Distur. var. if set to 0%, the controller does not account for disturbances. If increased, the controller becomes more responsive to sudden changes, which can help stabilize the process when disturbances affect the setpoint.

👌Recommendations for PID Tuning

- Kp

- If your system responds too sluggishly, try increasing Kp slightly

- If the system oscillates or overshoots the setpoint, reduce Kp slightly

- I-time

- This is how fast the system eliminates steady-state errors.

- If there is a slow drift toward the setpoint, reduce I-time for quicker corrections.

- If there is overshooting, increase I-time to slow down corrections.

- Dead Band

- If it’s set to zero, the controller will be constantly adjusting, which may cause unnecessary small corrections.

- If the system is too sensitive and fluctuates around the setpoint, try setting a small dead band to reduce unnecessary adjustments.

- S-time

- A shorter S-time makes the controller react quickly but may also cause unnecessary noise sensitivity.

- If the process is stable, keep it low otherwise,

- If the system appears jittery, try increasing S-time to smooth out responses.

- distur. var.

- If your process experiences sudden fluctuations (e.g., due to inconsistent ingredient flow or temperature changes), try gradually increasing the disturbance variable to see if stability improves.

- If the system is already stable, leave it at 0% to avoid unnecessary sensitivity.